Hydraulic Cylinders

How to get the best parts, with the best support, and the best delivery, at the best value!

Contents (click to jump to a section)

|

|

Introduction

Hydraulic cylinders are found in many industrial sectors, including construction, automotive, aerospace and manufacturing. Wherever linear pressure is required in a machine, hydraulic cylinders can be used, with units capable of exerting pressure ranging from a few kilos to many tonnes per square inch (PSI). They are known for being reliable workhorses that operate efficiently in many industrial contexts and require comparatively little maintenance.

Sizing, Dimensions & Part Numbers

Choosing the right hydraulic system for your application can be bewildering, with thousands of different components available. Fortunately, standard components are available in a variety of sizes, and can be ordered with standardised part numbers. We always keep an extensive range of cylinders and other hydraulic components in stock, so please don’t hesitate to get in touch for a chat with one of our service team to discuss the part you need.

How To Use This Guide

At Ranger Caradoc Hydraulics we specialise in integrated hydraulic systems, of which hydraulic cylinders play an important part. Customers come to us with a range of questions related hydraulic machinery. Some are buyers looking to source high-quality hydraulic products. Others are machinery or design engineers looking for technical support when designing prototype machines.

In all cases we provide impartial, technical expertise tailored to the needs of your business. We can suggest, design, supply and maintain all the hydraulic kit you need for your machines, all from one source.

An integrated approach to hydraulics results in compact, efficient machines with reduced admin and component costs. Our service extends to all hydraulic components and control systems, including cylinders, pumps, valves, power packs, couplings, hoses and fittings.

Here, we discuss how hydraulic cylinders work, how much they cost and the common mistakes made by design engineers when sourcing hydraulic cylinders for their applications.

If you have any questions while reading this guide please don’t hesitate to get in touch. We are happy to discuss your project and help you achieve the results you need within your budget.

Call us on 01299 896 953, or send us a message through our online contact form, and one of our team will get back to you shortly.

How Hydraulic Cylinders Work

Hydraulic cylinders are widely used in many different manufacturing machines and vehicles, as well as construction equipment. Technically they are motors or actuators that use pressurised hydraulic fluids to exert a linear, unidirectional force on a piston.

Hydraulic Cylinder Components

There are hundreds of different types of hydraulic cylinder used in industry. These can be differentiated by size, dimensions, part numbers and valve types. Cylinder design also varies based on application type and industry.

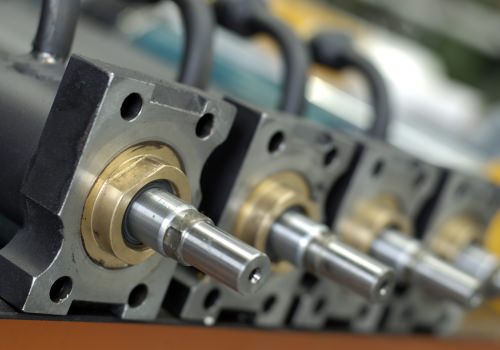

However, all hydraulic cylinders have certain core features in common. The housing of the cylinder is a cylindrical barrel, containing a piston linked to a piston rod, which moves forward and backwards. The cylinder is divided into two chambers by the piston, referred to as the cap end and the head end.

One end of the cylinder is sealed by a cap (also called a cylinder bottom) and the other, the cylinder head, has an opening from which the piston rod protrudes. The piston and its moving parts are secured through a series of mountings, hydraulic seals and sliding rings.

A hydraulic cylinder is a precision motor, with each component carefully engineered to safely maintain pressure and ensure smooth, efficient operation. The piston rods are manufactured from chrome-plated, cold-rolled steel, with the barrel made from a single, seamless steel cylinder.

The cap can be welded to the pressure chamber, or attached by bolts, steel threads or rods. Except when welded, an O-ring or hydraulic seal will keep the system airtight and maintain pressure between the cap and cylinder.

Seals are extremely important parts of hydraulic cylinders, crucial in preventing leaks, maintaining pressure and preventing damage.

Power Generation

Hydraulic cylinders do not work on their own. The motor requires a power generator, which takes the form of a hydraulic pump that feeds oil into the cap end chamber of the cylinder to power the piston. As the piston moves, pressurised oil in the head end is forced back into the fluid reservoir, creating a force cycle that maintains pressure on the system.

Calculating The Required Force

The output force applied to the piston rod is equal to the pressure in the cylinder, multiplied by the area of the piston.

So… Force (F) = Fluid Pressure (P) X Piston Surface Area (A)

This equation can be used to help determine the size of the hydraulic cylinder you need, based on how much force is required to power the application.

This rule applies to single acting, single rod cylinders and double acting, double rod cylinders (see below), where the piston surface area is roughly equal in both chambers, and so input and output pressures are the same.

In a double acting, single rod cylinder, however, the piston rod itself reduces the surface area of the piston in one of the chambers, thus reducing the force available for the reverse stroke.

Types Of Hydraulic Cylinder

A hydraulic cylinder can be single acting or double acting. This describes the way in which the hydraulic fluid acts on the piston.

- Single acting cylinders only exert fluid pressure on one side of the piston. In practice they are like hydraulic rams, forcing the piston rod out in a single direction. For retraction, the piston depends on external springs, flywheels or other cylinders to return it to its starting place. Single acting cylinders are widely used in internal combustion engines.

- Double acting cylinders, on the other hand, have fluid exert pressure alternately on either side of the piston. They are used when an application requires a force to be produced on both sides of the cylinder (e.g. to operate a crankshaft), or when the application lacks the external force required to return the piston to its starting position. Double acting hydraulic cylinders were commonly used in steam engines and on some large scale internal combustion engines, such as ship motors. They are also sometimes used in blast furnaces. However, they are now rarely used except in specialist applications.

Hydraulic Cylinder Designs

There are three main hydraulic cylinder designs currently used in industry, all of which we provide here at Ranger Caradoc. As with the cylinder type, the right design will depend on the application you need the component for, and making the right choice is essential to the success of your operation.

1) Tie Rod Hydraulic Cylinders

In a Tie Rod design, the cylinder barrel is enclosed by strong external steel rods, linking the two caps at either end. The larger the cylinder and the greater the pressure it has to withstand, the more rods will be needed. Large units may have up to 20 tie rods, and small units have as few as four. Tie rod cylinders are most commonly used in industrial settings. Because each tie rod can be easily removed, the cylinder is easier to access for maintenance than their welded counterparts.

2) Welded Hydraulic Cylinders

Welded hydraulic cylinders have no external tie rods. Instead, the caps are welded directly to the barrel. This allows them to be stronger and narrower than tie rod cylinders and can be miniaturised for use in machinery and engines. These are the cylinders you find in vehicles such as bulldozers, cranes and excavators.

3) Telescopic Hydraulic Cylinders

Telescopic cylinders contain a number of retractable, concentric welded barrels that are designed for when a long reach is needed. Only heavy duty cylinders are powered by hydraulic oil, and these can exert huge pressure of up to 2,000 to 3,000 lbs psi.

Valve Types

For the hydraulic fluid to be directed correctly through the system and into your cylinder, you need the right type of valve. In fact, a hydraulic system will not function at all without the right valves.

Valves are available in different sizes and materials. The size you need is based on the required flow speed of the hydraulic oil and the pressure in your cylinder.

There are three main types of hydraulic valve:

1) Directional control valves: These either stop the flow of hydraulic oil (check valves) or change its direction (spool valves).

2) Flow control valves: These valves determine the speed of the flow into the cylinder by increasing or contracting the opening at the valve point. Action is triggered by the speed of the flow, allowing the hydraulic cylinder to operate at a constant speed even when pressure drops in the system.

3) Pressure control valves: Pressure, or Throttle Valves expand or contract in response to the viscosity of the hydraulic fluid (indicative of the comparative pressure difference between the hydraulic cylinder and the rest of the system).

For a system to work as it should, it is critical that all parts work together in harmony.

Selecting the wrong parts can yield an inefficient and expensive system at best, and a completely failed product at worst. Unfortunately, many manufacturers make the mistake of specifying the wrong parts at the prototype design stage. This has long ranging implications for the performance of their machinery. In our next section we will explore what these common mistakes are and why they occur.

The 2 Most Common Mistakes When Buying Hydraulic Cylinders

There are two main mistakes that machine manufacturers fall into when sourcing hydraulic cylinders. Either the wrong size is ordered, or the wrong mountings. Both mistakes have serious implications for businesses and there are common reasons why they happen. Understanding the reasons for these mistakes makes them easier to avoid, especially with the assistance of a hydraulics specialist such as Ranger Caradoc.

This section explains the two errors, their implications and how to avoid them.

1) Wrong Size

As we saw in the previous section, the force a hydraulic cylinder can exert depends on its surface area and internal pressure.

To determine the correct size, you therefore have to work backwards from your requirements in terms of:

- Speed

- Force/strength, and

- Capability

It is a common mistake to misjudge these requirements and therefore choose the wrong size. The result is a cylinder that operates at the incorrect speed, or that lacks the capacity to carry out its function.

2) Wrong Mountings

It is important that a hydraulic cylinder is mounted correctly with the right components. Failure to do this can result in incorrect functions and problems with your warranty.

Approaching your machine as an integrated hydraulic system will help to avoid this problem. Issues most frequently arise when components are ordered on a part by part basis.

To function correctly, a hydraulic cylinder must have the appropriate:

- Fixed or swivel clevis ends.

- Micro or pivoting feet.

- Flanged, foot or trunnion mountings.

- Displacement.

Implications

Implications of making these mistakes range from product failure at one end of the spectrum, to poor performance and excessive running costs at the other. Warranty issues are also bound to come up when parts need replacing.

The solution to these mistakes

The solution to this is to work with a supplier that speaks your language and works with you to address your hydraulics requirements, which include ordering the correct parts. The business relationship starts not with the parts order, but with a solution-focused dialogue that results in a custom purchase to meet the customer’s specific needs.

How Much Should You Pay?

As we have seen, hydraulic cylinders vary widely in size and type, depending on your application and the force required.

Basic single acting cylinders can be purchased from as little as £30 per unit and double acting cylinders from £50-£800 per unit, but this doesn’t include installation, design or integration with other components.

When purchasing components only, the following four factors will affect the price you pay per unit.

1) Size

The side of the hydraulic cylinder will affect its price, with larger and more powerful components costing more than smaller ones. Bespoke cylinders will cost more than standard units, to reflect the additional design and fabrication time required on custom builds.

2) Batch Size

Suppliers can usually offer better prices per unit on large batches than small orders. This is a matter of economy of scale. A small batch frequently take as much input to set up and configure as a larger batch, so the costs per unit are correspondingly higher. However, a reputable hydraulics company will always be able to cater for small orders as well as large. Discounted rates may be available for repeat orders, regardless of the batch size.

3) Delivery Speed

Your required turnaround time will affect the total cost of your order. The more notice you can give a supplier, the better placed they will be to fulfil your order at a low-cost. Short turnaround and priority orders sometimes require the reallocation of resources, leading to higher costs. At Ranger Caradoc, our extensive manufacturing facility allows us to fulfil many of our orders in less than 14 days, while keeping our costs low.

4) Challenging Working Environment

Robust or specialist cylinders designed to work in extreme environments may cost more on account of the engineering challenges they pose. Hydraulic cylinders for hot or dirty environments require specialist tooling and tough materials, as well as rigorous testing. This adds to the expense of production. Also, specialist components are often manufactured in smaller volumes than standard ones, which also affects cost. This rule isn’t strictly the case with Ranger Caradoc. We accept that all engineering environments have their challenges. Our approach is not to provide a particular product as the solution to your problem, but to first understand your requirements and design the appropriate response, in the most cost-effective way possible.

Purchasing From Ranger Caradoc

At Ranger Caradoc, we stock a huge range of hydraulic cylinders suitable for all industrial sectors. These include standard size single and double acting cylinders - both welded and tie rod models – as well as two, three and four stage pin-mounted telescopic cylinders. There are plenty of variants available, with different configurations of feet, flanges, trunnions, clevis and swivel bearing mountings.

If you can’t find what you need from our catalogue, we can manufacture you custom-designed cylinders of up to 200 mm bore and 3,500 mm stroke.

All our products are available in large quantities for single and repeat orders, at great prices and short lead times.

Of course, we are not simply a parts seller. This is only one aspect of what we do. Our real strength lies in our design and technical expertise, coming into your business to understand your specific engineering requirements, and suggesting a bespoke solution from all available options. In the next section, we will explain our way of working and why you should consider Ranger Caradoc for all your hydraulic system requirements.

Buying From Ranger Caradoc Hydraulics

Why choose Ranger Caradoc when looking for a hydraulic solution, as opposed to one of our competitors? Firstly, having been set up in 1977, we now have 40 years’ experience providing hydraulic components, control systems and complete hydraulic solutions to equipment manufacturers in a wide range of industries.

Our Service Ethos

Secondly, our team are professional engineers with solid industry expertise and a passion for their job. The people you speak to on the phone and throughout your project are the same people working on the design and machining of your parts.

We value transparent communication, with set-in-stone delivery times and straightforward pricing, along with the following service guarantees:

- Our team will have the expertise to understand how your kit works.

- We will offer free and impartial advice to help you design prototype equipment.

- We listen to your engineering problem and propose the parts you need – You don’t need to give us part numbers.

- If something does not work we will work on it until it does.

- There are no hydraulics services that we can’t provide. If you need us we can help you take your project from the design stage, to prototype, to full production.

Why Choose Us?

What about the practical capacity that backs up our service guarantees? We have the infrastructure, personnel and established supplier relationships to offer great value and service delivery for all our customers. Here are our main strengths and how they allow us to deliver for you.

Don’t feel you need to take our word for it, however. Please get in touch for a free quote and let us show you our services first-hand!

Product Catalogue & Bespoke Components

We offer a comprehensive range of hydraulic cylinders, which we extend regularly in response to market needs and new technologies. We manufacture many of our own components, and also supply standard cylinders from some of the world’s best manufacturers.

We offer a great range of single and double acting cylinders in both metric and imperial sizes. We also fabricate bespoke cylinders in a range of sizes, alongside a large selection of valves, power packs, couplings and fittings. Our aim is for you to find all the components you need under one roof and with one convenient invoice, to avoid the hassle of having to liaise with multiple suppliers.

Large Order Fulfilment Capacity

We have expanded our business significantly over the past few years, increasing our manufacturing capacity and product range. In 2013 we moved our cylinder manufacturing facility to a new factory in West Bromwich, and plenty of storage capacity. This gives us an unrivalled stock of standard parts and short lead times on all bespoke orders. We can also fulfil large-volume orders from stock without you having to wait for us to order parts in from elsewhere.

Short Lead Times

Our new facility lets us offer a short lead time of around 14 days or less for all bespoke orders. This cuts your waiting time considerably and enables us to meet all our delivery promises.

Accurate Design Service

We offer a specialist design service to develop integrated hydraulic systems in conjunction with your design team; all the way from prototype and testing, to approval and manufacturing. Depending on your requirements, we can use either standard or special manifolds that incorporate all the cylinders, valves and other components you need to operate your machinery. We are happy to accept the challenge of any project, no matter how complex, and have the manufacturing capacity to deliver in both small and large volumes.

Good Quality & Reliability

The quality of our products and services are second to none, the proof being the many happy clients we have worked with over four decades in business. Many of our clients have worked with us for many years and we are fortunate to have repeat business with some fantastic companies in many different sectors. Our customers include machinery manufacturers from the agricultural, quarrying, forestry, vehicle and construction tool sectors, among others.