There are two most commonly used types of hydraulic cylinder: single acting and double acting cylinders. One type of cylinder is not innately better than the other and the decision is not normally an either/or choice.

Rather, both single and double acting cylinders have their uses and applications where they are better suited than the other type. In this article we take a brief look at each type, explaining how they work and the applications they are found in.

Single Acting Hydraulic Cylinders

In a single acting hydraulic cylinder, fluid pressure is exerted on one side of the piston only, so that the piston rod acts like a hydraulic ram, pushing outwards but not pulling back on the retract movement. These cylinders need an external force to retract the piston rod, such as a pump, motor or set of internal springs.

Advantages

- Compact and space-efficient

- Simple structure

- Reliable and easy to maintain

- High pressure and force potential

Disadvantages

While high quality single acting hydraulic cylinders are reliable units, those equipped with retractable springs are vulnerable to component failure as the springs wear out. This manifests as a gradual reduction in force on the retract movement. They are also more difficult to seal and can become damaged over time through exposure to corrosive fluids.

Uses

Construction plant, internal combustion engines, reciprocating engines, pumps, hydraulic rams and jacks.

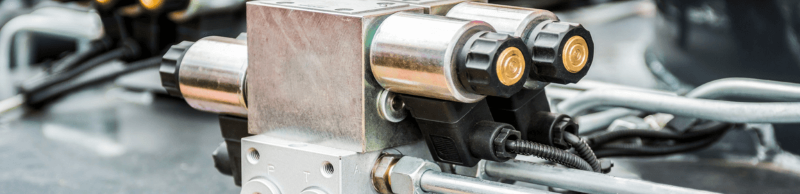

Double Acting Hydraulic Cylinders

A double acting cylinder is capable of pressure being exerted on either side of the piston alternatively. This means that both outward and retraction movements can be achieved under the cylinder’s own pressure without an external source of power. This can be used simply to return the piston to its starting position, or to apply an alternating force on both sides of the cylinder – for instance to operate a crankshaft.

Advantages

- Good stock availability – these are the most commonly used hydraulic cylinders.

- Energy-saving. The piston will always return to its starting point.

- Less hydraulic fluid needed.

- Rugged & reliable.

- Controlled acceleration.

- Good repetitive accuracy.

- Precisely definable stroke measurements.

- Huge variety of potential applications (see below).

Disadvantages

No specific cons associated with double acting cylinders, although many are out performed by single acting cylinders in force output.

Uses

large-scale engines (e.g. ship motors), industrial furnaces, digging machines, lift shafts, steering mechanisms, any application where an external power source is not available to retract the piston.

Control

The decision between a double acting or single acting cylinder often boils down to one of control. How much precision is required when exerting force in your hydraulic system? If you need to exert a large force to move a load in a single direction – e.g. for heavy lifting applications – a single acting cylinder may be sufficient. However, if you need to direct a load in two directions or have greater flexibility over the movements of the cylinder, a double acting cylinder will give you more control.

Download Our FREE Product Brochure

We have a range of single acting and double acting hydraulic cylinders available for immediate dispatch from our extensive stock. Click here to check our current availability. For questions and product enquiries, please call 01299 896953.