Hydraulic cylinders are a crucial part of hydraulic systems. With a pressurising engine, they provide the rapid physical displacement and replacement of fluid that hydraulic lines, lifts, and presses need to maintain their strength and force.

John Wheway

Recent Posts

Topics: Hydraulic Cylinders

When Would You Be Likely To Need A Bespoke Hydraulic Cylinder?

Several hundred different standard-design hydraulic cylinders exist for a variety of applications, meaning you don’t normally need to pay to have a cylinder custom-designed. However, in some cases, none of the standard options fit, or you may require a specific performance output not matched by an available component. That’s where bespoke hydraulic cylinders come in.

Topics: Hydraulic Cylinders

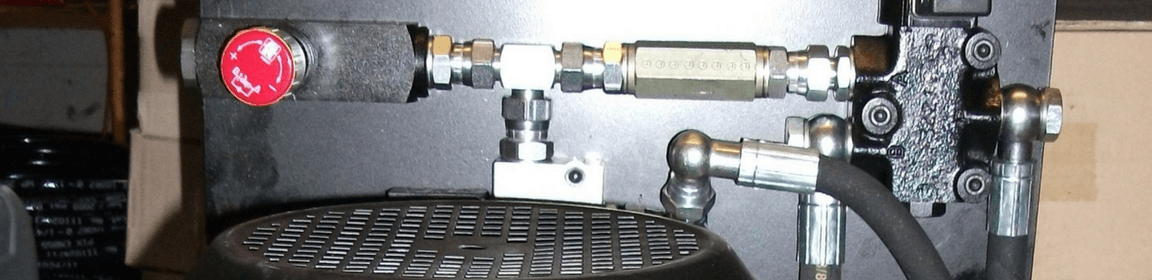

The Big Advantage To Using A Manually Operated Hand Valve

Hydraulic valves control the directional flow of fluids through a hydraulic system. Choosing the right type of valve is highly important for the system’s overall function. From solenoid to multi-block directional valves and from directional to pressure control valves, it’s not always easy to figure out which valve is the best for you.

Topics: Hydraulic Hand Valves

Selecting the right hydraulic pump is vital to a system’s proper function and longevity. There are numerous types of hydraulic pumps to suit different purposes. In this article we explain which pumps can work for which systems.

Topics: Hydraulic Pumps

10 Factors To Consider When Purchasing A Hydraulic Power Pack For Your Project

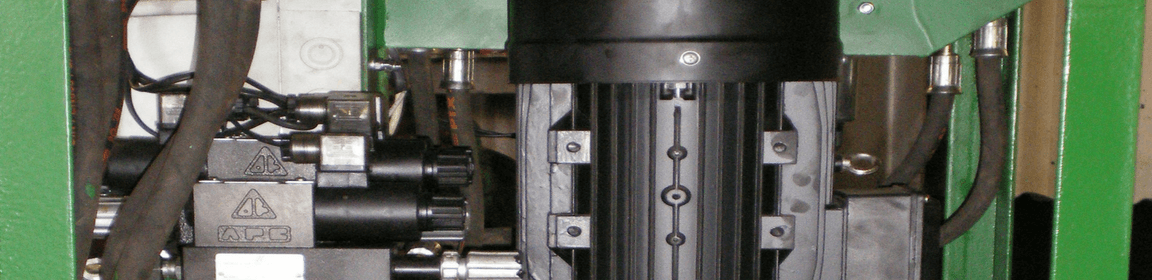

The hydraulic power pack is arguably the most important part of the hydraulic system. It consists of specific components, sub-assemblies, and accessories. The pack’s function is to supply hydraulic power to the system.

Topics: Hydraulic Power Packs

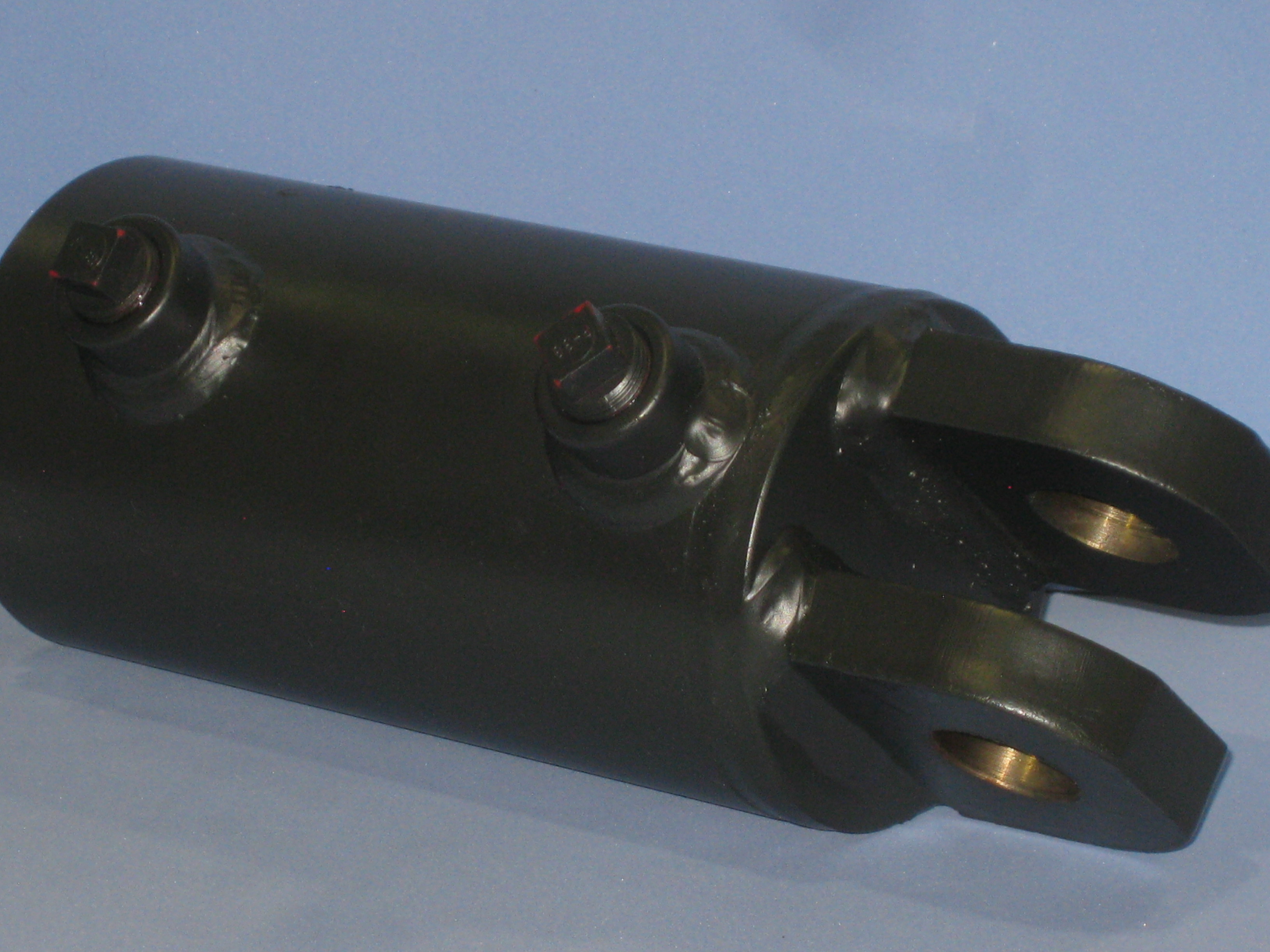

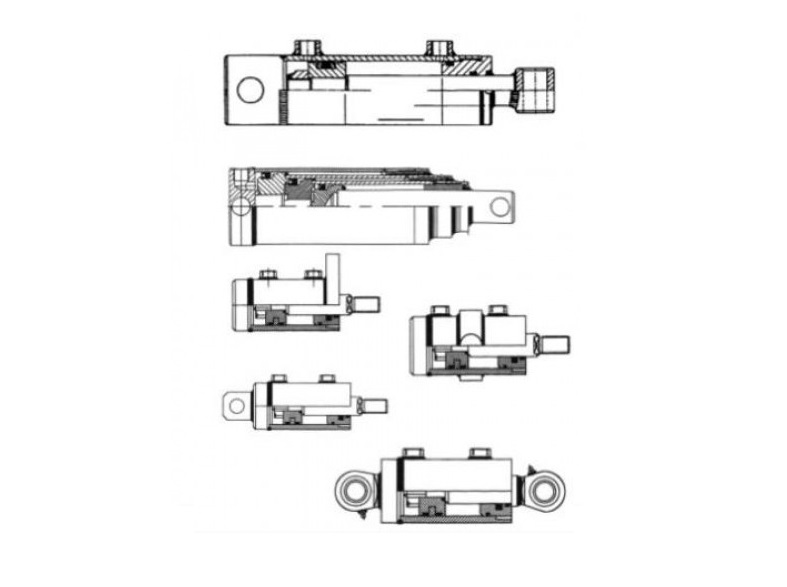

How To Choose The Right Hydraulic Cylinder For Your Application

Hydraulic cylinders come in a wide variety of types, designs, and sizes. You need to have a fair understanding of your project needs in order to choose the right one. Here’s how to narrow down your choice to the best cylinder.

Topics: Hydraulic Cylinders

We’re getting ready to re-locate our Great Witley office to a unit next door to our new factory in West Bromwich. This will put our sales and customer service team closer to our manufacturing division, and enable us to provide a more responsive service to our customers.

Topics: Insider

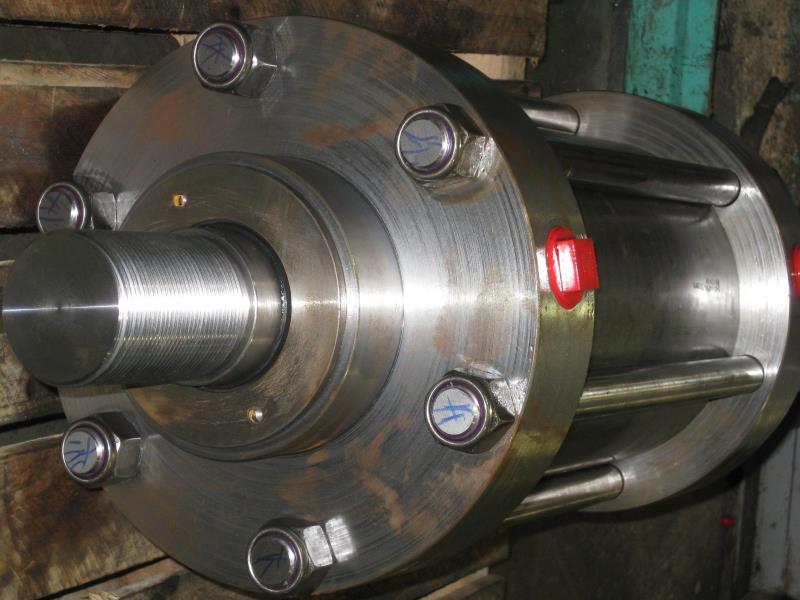

What Is Cushioning (In Hydraulic Cylinders) And Why Is It Important?

A hydraulic cylinder is a mechanical actuator which gives a unidirectional force via a unidirectional stroke. A tube in which a piston operates under the action of fluid pressure is referred to as cylinder housing. Cylinder cushioning is an arrangement intended to regulate the speed of the piston as it ends the stroke. The piston’s deceleration begins when the plunger approaches the end of the cap.

Topics: Hydraulic Cylinders

What Are Tandem Hydraulic Cylinders & How Are They Used?

Tandem hydraulic cylinders are versatile and adaptable components and can be used in a variety of mechanical applications. Completely customisable, they can provide the perfect solution when single hydraulic cylinders lack the force required to set machinery in motion. Yet for such a powerful piece of equipment, they are surprisingly simple in design.

Topics: Hydraulic Cylinders

Preventative Maintenance – How To Prevent Faults In A Hydraulic Cylinder

Preventative maintenance is a strategy to reduce repair bills and keep machines running efficiently. Many businesses offer planned preventative maintenance (PPM) as a paid service. We don’t, although there is a strong argument that PPM extends the life of industrial equipment and can save money in the long term compared with repair costs and spare parts.

Topics: Hydraulic Cylinders