Hydraulic cylinders come in a wide variety of types, designs, and sizes. You need to have a fair understanding of your project needs in order to choose the right one. Here’s how to narrow down your choice to the best cylinder.

Cylinder Type

Depending on your project, you have to select one of the two common hydraulic cylinder types:

- Single Acting – exerts fluid pressure on one side of the piston. This type is commonly used for internal combustion engines.

- Double Acting – exerts pressure on either side of the piston. The strength can be controlled in both directions with a regulator. This type is excellent for applications that require a high external force.

Cylinder Design

Choosing the right hydraulic cylinder design depends on your application.

- Tie-Rod – Employs steel rods outside the cylinder housing for added stability and strength. This design is suitable for the majority of general industrial applications, such as machine tools. The maximum operating pressure is 3,000 psi.

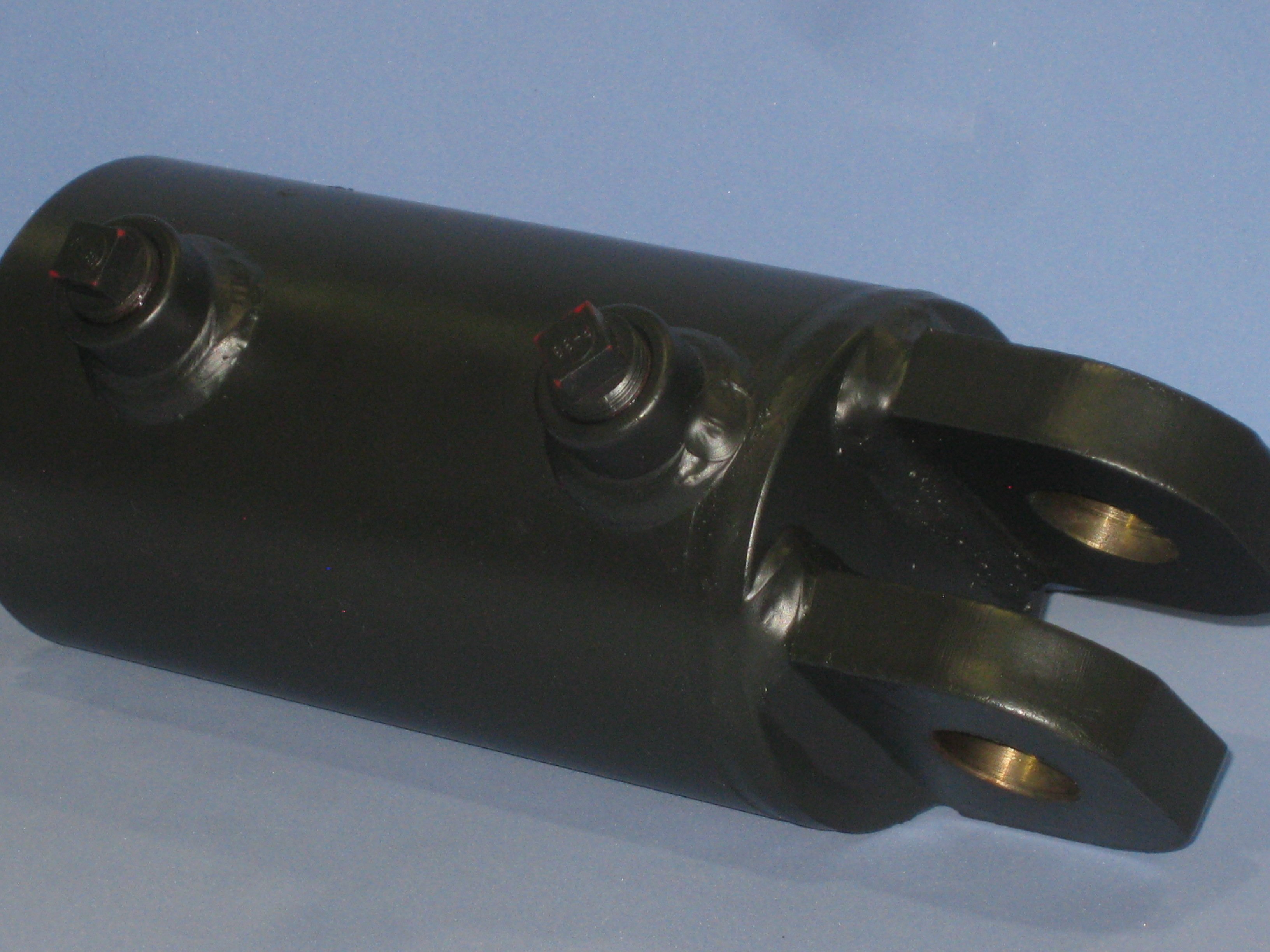

- Welded - Have heavy-duty housing without employing tie rods. The barrel is welded directly to the end caps. These cylinders can work at operating pressures up to 5,000 psi and even higher. They are used for heavy-duty applications, such as presses or steel mills and heavy vehicles, such as cranes and excavators. This design is suitable for rough environments with severe temperature fluctuations.

- Telescopic – Made of several cylinders stacked on top of each other. They can have up to six stacked components. This design is useful when a long reach is required.

While there is a wide selection of standard hydraulic cylinders, many projects require a special approach. Customised cylinders may be an excellent way out, reducing wear and tear while extending the lifespan of the system.

Mountings

In order to function correctly, a hydraulic cylinder should have the right mountings. Failing to do so can lead to costly breakdowns, which aren’t covered by warranty. The type of cylinder mounting depends on the type of cylinder body and the direction of the load.

- Stationary – Used when load moves in a linear direction. Front head flange and side lug mounts are usually required.

- Pivoted – Generally used when a load moves through an arc. Trunnion and clevis mounts are excellent for the job.

Whatever the application you’re purchasing the cylinders for, it’s important to view the machine as an integrated hydraulic system. This can help you avoid mounting issues, which often occur when components are purchased separately.

Professional Assistance From Ranger Caradoc

At Ranger Caradoc, we keep a wide range of hydraulic cylinders in stock, and our experts are always ready to help you find the right component and mountings for your application. For more information, please download our free e-book: The Buyer’s Guide To Hydraulic Cylinders.