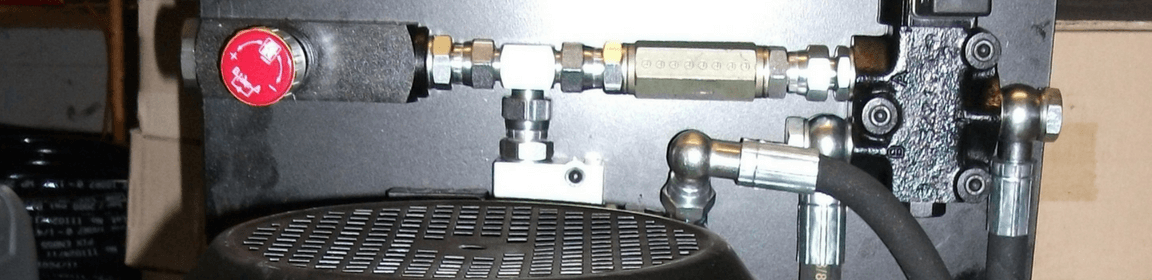

The hydraulic power pack is arguably the most important part of the hydraulic system. It consists of specific components, sub-assemblies, and accessories. The pack’s function is to supply hydraulic power to the system.

Hydraulic power packs vary in size and composition. They can either service a large system or be the heart of a basic hydraulic unit. Depending on the parameters of your project, different types of power pack will be more or less appropriate.

1) Power Requirements

In order for the hydraulic power pack to be functional, it’s important to identify what it needs to power and in what sequence. When identifying force and power requirements, the manufacturer has to consider the size, the number of actuators, volume and distance of piping runs.

Depending on these parameters, the manufacturer can make a decision on whether a bespoke hydraulic power pack needs to be designed or a pre-engineered unit is sufficient.

2) Operating Environment

The temperature, weather conditions, and elevation are all factors to consider when designing a power pack. For example, a unit used at sea may require special marine certifications and need a salt and water-resistant protective coating.

Different temperatures dictate the need for heating or cooling components as well as temperature sensors.

3) Noise Limitations

Depending on the location and purpose of the hydraulic pack, the manufacturer can regulate the noise output. For many applications, maximum noise levels are stipulated by regulations. Ensure your chosen power pack is compliant.

4) Energy Efficiency

The energy efficiency of a power pack is vital for some applications. Even though it’s important to strive for energy efficiency as much as possible, in some cases, the manufacturers may forgo energy efficiency in order to achieve the desired output.

The upfront cost of an energy-efficient power pack may be higher. However, it costs less to run and can decrease the total cost of ownership.

5) Cost

The cost of a hydraulic power pack is often the most important thing to consider when manufacturing the product. You get what you pay for, and although there are many low budget power packs on the market, it is often worth spending a bit more on a higher quality unit. This may yield longer term savings on power consumption and increased reliability.

6) Size

The size of the machine you are planning to use the hydraulic pack for directly affects the size of the power pack.

Micro-units are suitable for such small projects as log splitters or electric gates. Meanwhile, if you need a pack for heavy-duty lifting equipment, it has to be sizeable. Standard power units are designed for in-plant operation.

7) Bespoke Or Standard?

Depending on the project requirements, you may need a bespoke power unit. Standard power pack equipment can come in many variations suitable for the most popular uses. However, many OEMs, especially those dealing with large projects, opt for special design. If you need a large volume of power packs, ordering bespoke can be as cost-effective as purchasing standard components, whereas bespoke is likely to be costlier for small volume orders.

8) Manufacturer’s Reputation

The power pack is the heart of your hydraulic system. Failing to find a respectable manufacturer can lead to problems with the project. Whether ordering bespoke or standard units, it’s important to check out the manufacturer’s credentials and portfolio.

9) Maintenance Requirements

Even the best power units require regular maintenance. Find out what type of maintenance your power unit needs and how much it costs. Sometimes the total cost of ownership can be higher than you expect.

10) Technological Suitability

New technologies are appearing in the hydraulics industry on a regular basis. Make sure that the power unit is up to date with technological advances and is likely to remain current throughout its working life. If you are working with highly advanced equipment, you may need to order a bespoke power unit.

Hydraulic Power Packs From Ranger Caradoc

At Ranger Caradoc Hydraulics, we have a wide selection of hydraulic power packs, from standard to bespoke mini units. If you need a tailored solution, we are always ready to work on a new design to deliver the best performance at the best price.

For more information about power packs and our services, please download our free e-book, The OEM Guide To Hydraulic Systems.